A decision support system for the banana business

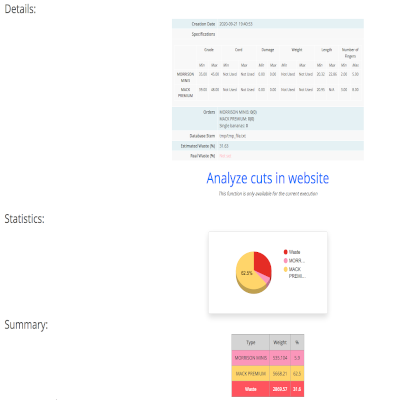

OPTIcut is a cutting-edge web-based decision support system offering precision agriculture in the banana business. It uses state of the art artificial intelligence and 3D image processing algorithms providing optimized cutting strategies and fruit profiles tailored to each farm. Banana hands are cut into clusters for packing. This generates variable amounts of fruit waste depending on the cutting strategy used. Cutting strategies are currently based on human experience and their number can be exponential. Therefore, there is a clear need to produce data driven optimized cutting strategies which can minimize waste and maximize profit. OPTIcut also offers producers the capacity to estimate the amount of fruit available in every farm (fruit profiles), per type of cut and to record fruit damage to make strategic decisions.

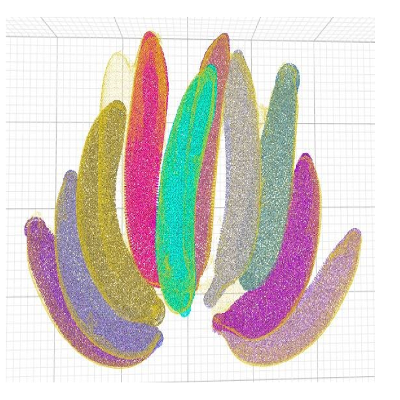

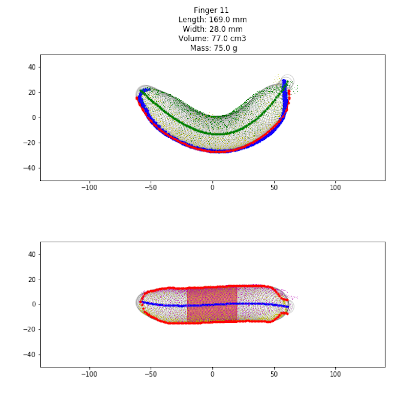

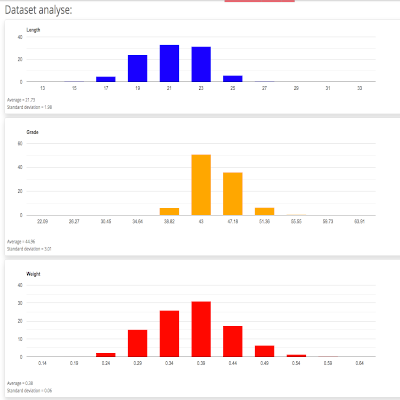

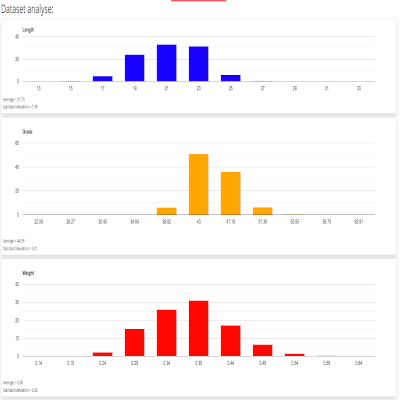

Traditionally fruit profiles are done by manually collecting and measuring a small percentage of bunches and cutting the banana hands to the specifics of a single cut type. This is time consuming,lacks precision and adds to fruit waste as every finger has to be cut off the hand. OPTIcut uses state of the art 3D image techniques combined with Artificial Intelligence to perform fruit measuremts at a fraction of the time, and without damaging the fruit. These measurements are recorded into data sets to for later use by OPTIcut to:

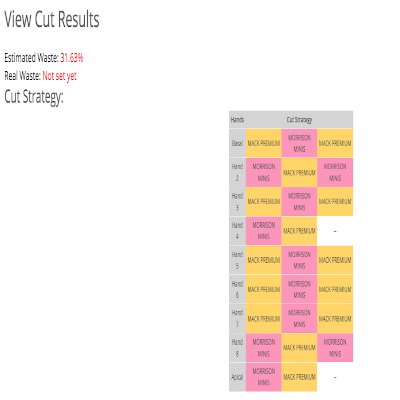

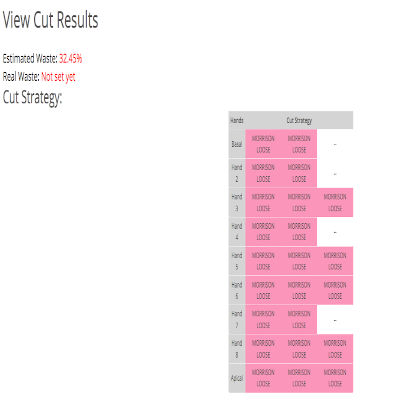

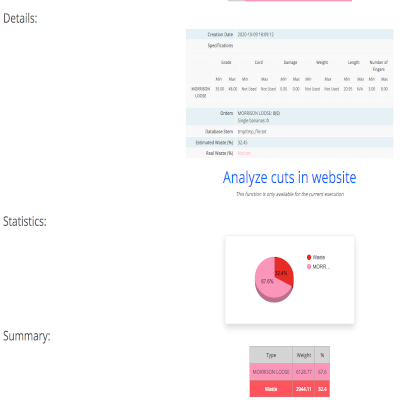

Bananas are packed in clusters. These clusters are constrained by the length, width and number of fingers which command their price. Daily cutting strategies are essential to fulfil orders. These strategies are created from previous experience. They dictate the levels of waste and profit. Finding the best cutting strategy is not computationally possible due to time constraints. OPTIcut uses artificial intelligence to produce optimized cutting strategies based on historical data.

Fruit profiles (total kilos available for each type of cut) are used to measure the volume capacity of each farm for each type of cut. Some farms are better suited for a particular type of cut. A typical packing facility process 4000 bunches a day. Currently producers collect daily fruit profiles based on 10 to 15 bunches. Every finger needs to be cut and measured. This is labour intense and prone to errors. All this fruit is wasted as there is little market for single fingers. Fruit profiles for any type of cut can be produced by running OPTIcut with the specific cut measurements. The software also allows users to combine different cuts together and measure overlapping.

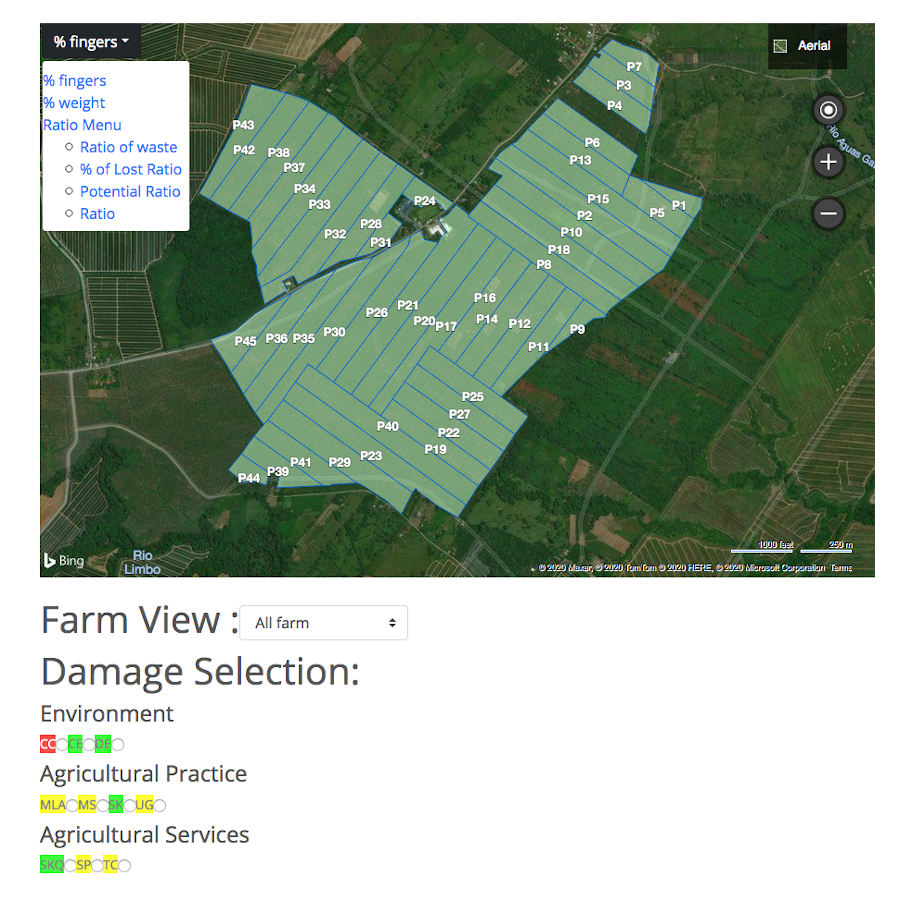

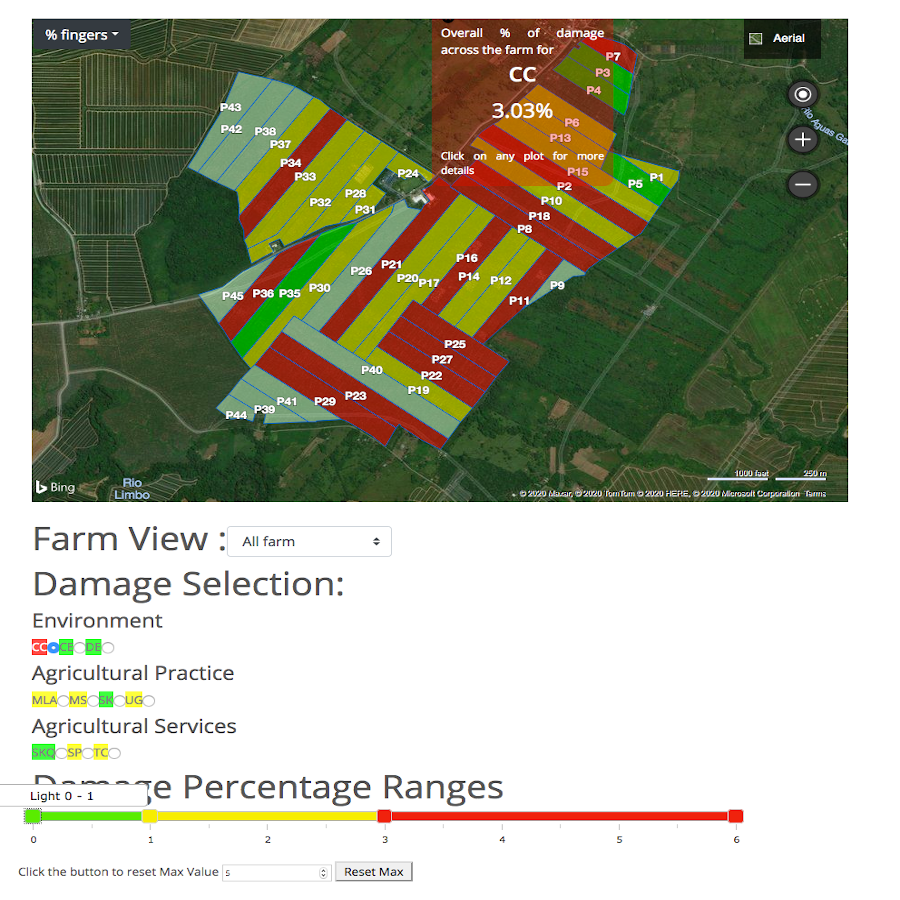

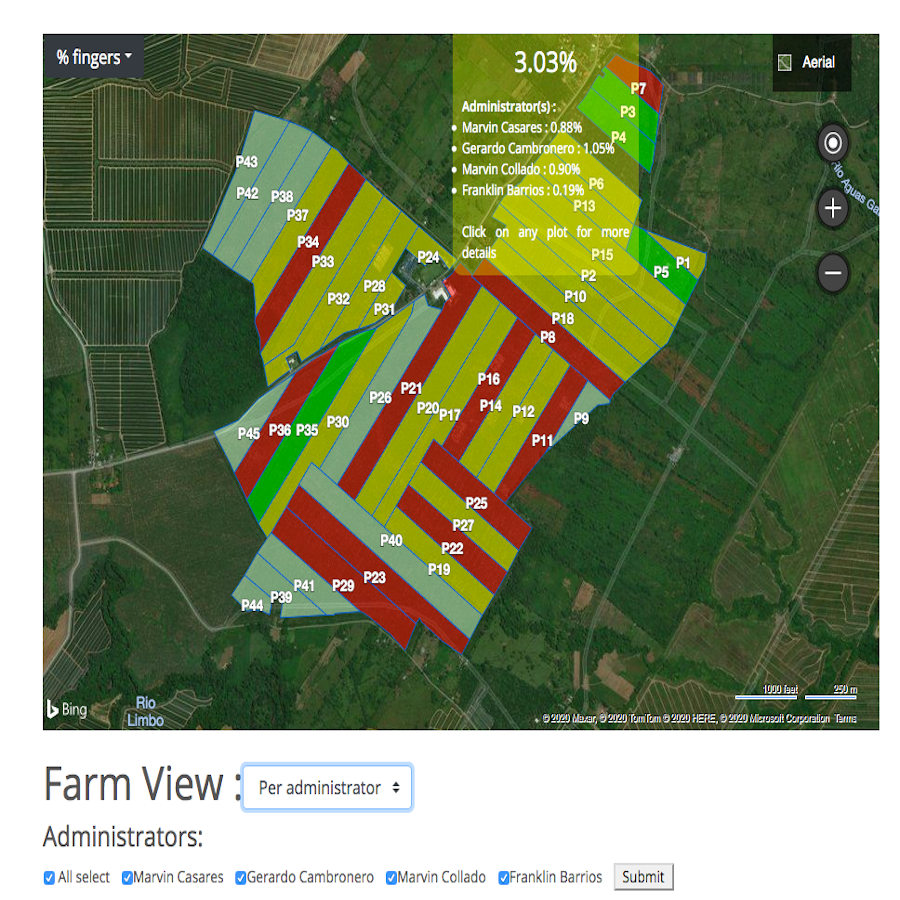

OPTIcut provides producers with tools to record fruit damages. This data can them be used by the producers to visualize, by using satellite images, how the different damages are spread across the farm. User can visualise damages:

Damages can be grouped by

Results are presented in terms of:

For further information, please feel free to contact us at:

OPTIcut

Prof David Elizondo (PhD)

elizondo@dmu.ac.uk

Copyright © 2020 Program Produced by De Montfort University, Leicester, England.

All Rights Reserved.

Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or De Montfort University. Neither the European Union nor the granting authority can be held responsible for them